Our 3D Printing Metal Solution

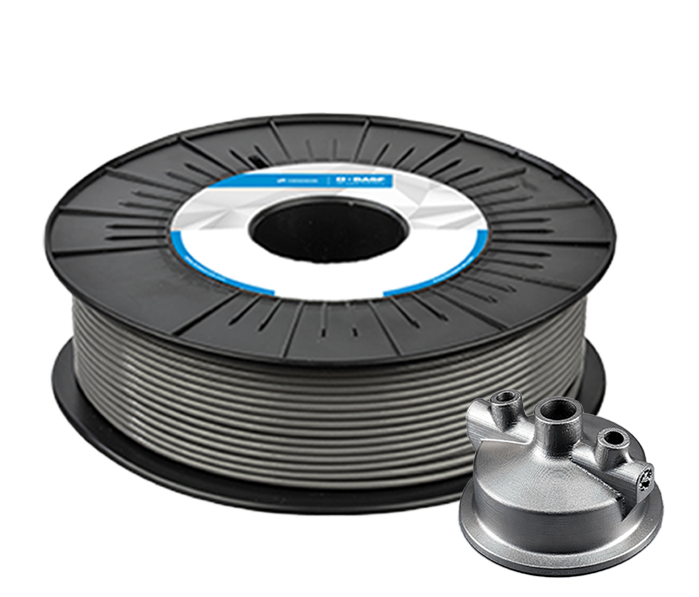

Ultrafuse® 316L and 17- 4 PH

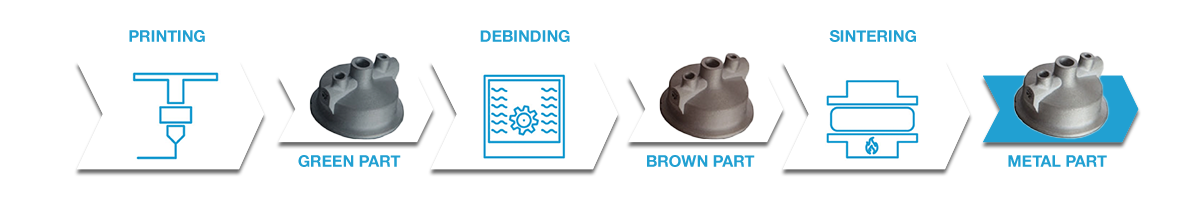

Parts printed with Ultrafuse® 316 L or 17-4 PH metal filaments obtain their final properties, including hardness and strength, through the catalytic debinding and sintering process.

The catalytic debinding technology was eveloped and introduced by Forward AM and has emerged as the industry standard.

Discover more at our Useful Resources

Ultrafuse® Support Layer*

Ultrafuse® Support Layer filament developed to be used in combination with Ultrafuse® Metal Filaments.

When printed between support and the object, it creates a barrier during sintering and facilitates the separation of support from the metal part.

Ultrafuse® Support Layer is not developed to print stand-alone parts and should be printed as a layer attached to the support structures in dual extrusion prints.

*Ultrafuse® Support Layer. This product is not intended for sale, distribution or use in the US and Canada and is not available to our customers in those countries.

While the descriptions, designs, data, and information contained herein are presented in good faith and believed to be accurate, it is provided for in- spiration only. Because many factors may affect processing or application/use, we recommend that you perform independent tests to determine the suitability and proper use of a product for your particular purpose.

NO WARRANTIES OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE MADE REGARDING PRODUCTS DESCRIBED HEREIN, OR THAT THIS CONTENT MAY BE USED WITHOUT INFRINGING THE INTELLECTUAL PROPERTY OF OTHERS. IN NO CASE SHALL DESCRIPTIONS, INFORMATION, DATA, OR DESIGNS DESCRIBED HEREIN BE CONSIDERED A PART OF OUR TERMS AND CONDITIONS OF SALE.

We guide you step by step

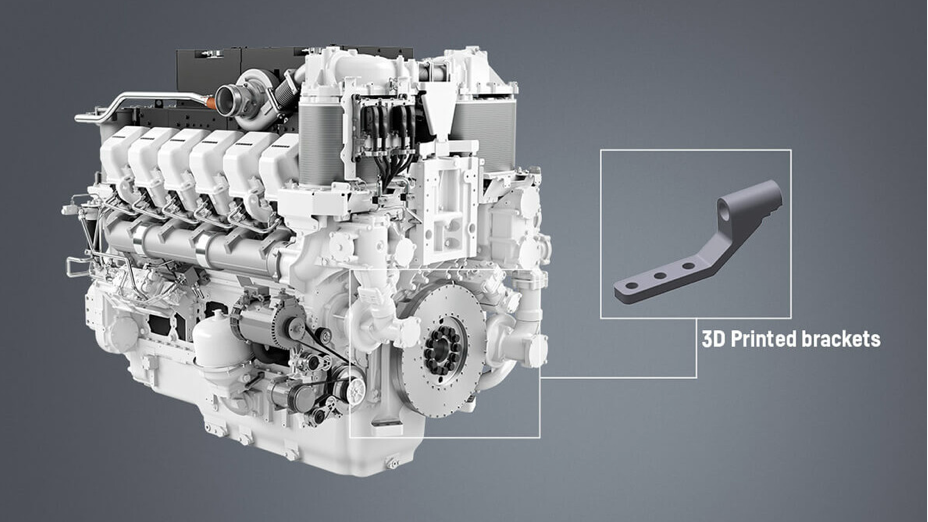

Printing with an Ultrafuse® Metal Filament is very similar to plastic FFF printing, however; there are subsequent processing steps that dictate the specific practices to increase the probability of successfully producing a full metal part. Once filament is loaded, flow has been calibrated, and the desired parts have been sliced, printing can begin.

First time printing Metals? At our useful resources section you will find everything you need. Do you want to see instructions? Take a look into our tutorial videos.

DEBINDING & SINTERING

Once your parts are printed using Forward AM's Ultrafuse® 316L or 17-4 PH metal filaments, the next critical step is getting them debound and sintered. This process unlocks the true potential of metal 3D printing, transforming your parts into full-strength metal components - a key differentiator from typical FFF 3D printing. To support you through this crucial stage, we've partnered with Elnik Systems, GmbH and DSH Technologies, LLC to manage the debinding and sintering services. Leverage their expertise and advanced capabilities to efficiently process your metal 3D printed parts.

Useful Resources

General Metal Resources

Ultrafuse® 316L

- Technical Data Sheets EN, FR, ES, DE, ZH

- User Guidelines

- Debinding Simulation Guidelines

- Process Guidelines

- Safety Data Sheets EN, other languages

- Print Profiles;

Raise 3D

Prusa

BCN3D

Download via Ultimaker website

Ultrafuse® 17-4 PH

- Technical Data Sheets EN, FR, ES, DE, ZH

- Technical Data Sheet

- User Guidelines

- Process Guidelines

- Safety Data Sheets EN, other languages

- Print profiles

Raise 3D

Prusa

BCN3D

Download via Ultimaker website

Ultrafuse® Support Layer

Available downloads

- Technical Data Sheet: EN, FR, ES, DE

- User Guidelines Support Layer

- User Guidelines Metal

- Debinding Simulation Guidelines

- Process Guidelines

- Safety Data Sheet: EN, other languages

- Print Profiles;

BCN3D

Raise 3D

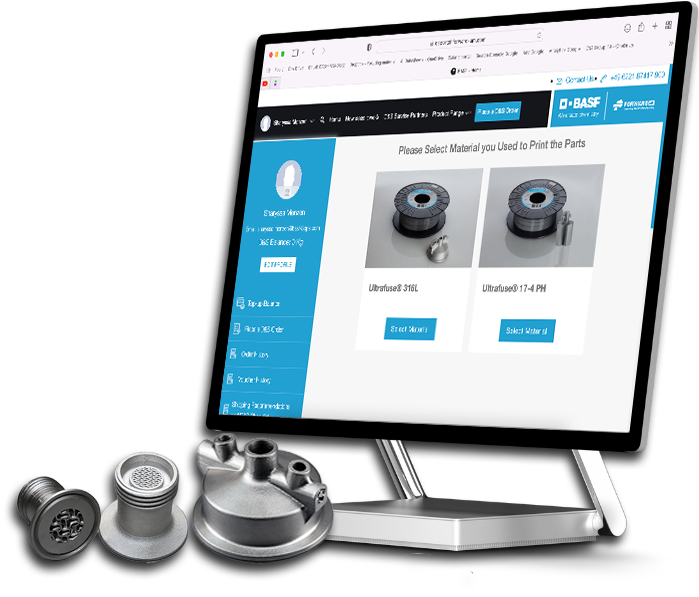

Debinding & Sintering Portal

Forward AM partners with Elnik Systems and DSH Technologies to offer expert-driven debinding and sintering services for our Ultrafuse Metal 3D printing solutions. This transition ensures customers receive the highest level of support as we advance metal additive manufacturing.

See our D&S Service Overview for more details.

Professional 3D Printing Service

It's also possible to let a service bureau do all the work. Professional 3D Printing Services such as our partners Sculpteo are your additive manufacturing production center from 1-100k parts. With our metal materials for your application, you’ll get the parts you need in just a few clicks.

Order Ultrafuse® 316 L or Ultrafuse® 17-4 PH Printed Parts directly from Sculpteo.

Quick start with Ultrafuse® Metal Filaments

Recommended processing parameters

| Nozzle Temperature | 230 – 250 °C / 446 – 482 °F |

| Build Chamber Temperature | - (Fan off) |

| Bed Temperature | 90 – 100 °C / 194 – 212 °F |

| Bed Material | Glass + approved glues* / polyimide tape (*Magigoo® suggested) |

| Nozzle Diameter | ≥ 0.4 mm |

| Print Speed | 15 - 50 mm/s |

| Scalling |

XY 120 % ; Z 124 % |