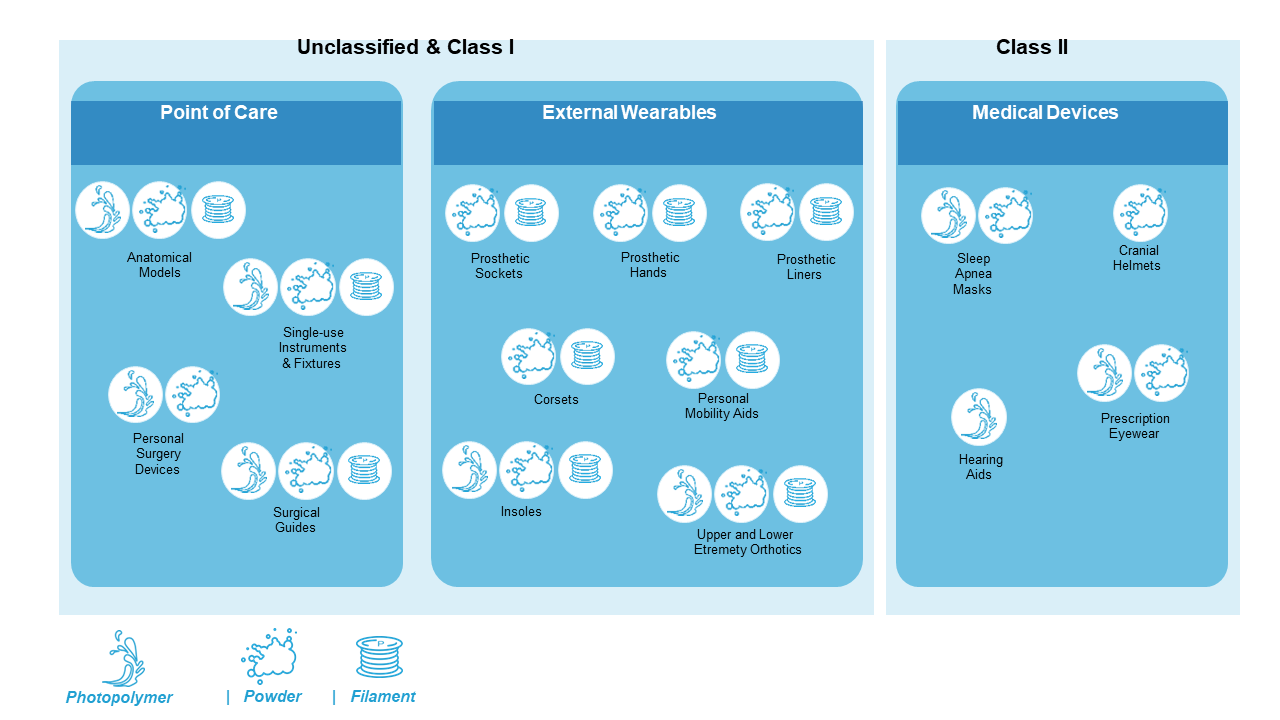

3D Printing for Orthotics and Prosthetics

Customization to the patient´s anatomy eliminates the need for implant adjustments, provides efficient fit and enhancing functionality of the damaged or deformed part

Additive Manufacturing for the O&P Industry

BASF Forward AM offers one of the broadest portfolios of high-performance materials, consultancy expertise, simulation know-how, a global printing network and post-processing capabilities - all in the quality known from BASF since 150 years.

Additive manufacturing fabricates custom implants of any complex shape and in the exact geometric feature, which is not previously possible by using traditional manufacturing techniques. Various benefits of additive manufacturing are as under:

- Perfect-fit production depends on the patient´s needs

- Offers unlimited geometric freedom

- Precise setting of desired elasticity

- High bio-compatibility

- Faster availability, shorter build times

- Fully automated and digitalized manufacturing

Real-Life Applications

Discover real life projects and find out more about Additive Manufacturing for the O&P industry in our use cases.

3D Printing Workflow for Orthotics and Prosthetics Professionals

O&P professionals integrate 3D printing to their workflow more and more - read all about a real-life example of a wrist cast.

Mold Improving Fitting and Comfort of ProsFit Prosthetics Sockets

Today amputees requiring prosthetic limbs have to put up with often uncomfortable, poorly fitting sockets. A collaboration between ProsFit and Forward AM now looks set to raise their quality of life.

Innovating with Exoskeleton Orthotics for Spinal Cord Injury

Discover how a team from Delft University of Technology 3D prints an exoskeleton with Forward AM's filaments.

How Additive Manufacturing Lends a Helping Hand

Read about how the Victoria Hand Project makes highly functional prosthetic devices possible for developing countries - 3D printed on-site and on-demand with Forward AM’s filament Ultrafuse® PLA, and with the help of a dedicated network of clinicians.

Download our 2023 Orthotics & Prosthetics Brochure

3D Printing Materials Recommendations for O&P

Photopolymers

Our Ultracur3D® photopolymers are based on BASF‘s decades of experience in polyurethane research and production. Benefit from the broad range of advanced photopolymer resins for footwear applications.

Ultracur3D® ST 45

Multi-Purpose Resin with Optimum Toughness and Processing Speed

Ultracur3D® ST 80

Multi-Purpose Resin Targeting the Lowest Cost per Part

Ultracur3D® ST 1400

Multi-Purpose Resin with Superior Toughness and Durability

Ultracur3D® RG 35

Rigid Resin with Optimum Combination of Strength, Stiffness and Temperature Resistance

Ultracur3D® EL 60

Flexible Resin with Quick Elastic Response and Low Hardness (Shore 75 A)

Powders

Our Ultrasint® polymer powders set new standards in Additive Manufacturing for the footwear industry as they enable various applications flexibility, elasticity and excellent processability.

Ultrasint® TPU01

Thermoplastic Polyurethane Powder for HP Jet Fusion Printers

Ultrasint® TPU 88A

Thermoplastic Polyurethane Powder for durable parts with excellent flexibility

Ultrasint® PA11

Bio-Derived PA11 Powder for Durable Parts with Exceptionally High Toughness

Ultrasint® PP 1400 Black

Advanced Polypropylene Powder for a Wide Range of Innovative Applications

HP 3D High Reusability PP enabled by BASF

Fully functional polypropylene for use on HP JF5200 series printers

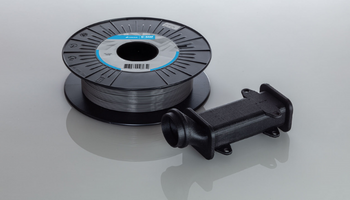

Filaments

Our experts for Fused Filament Fabrication (FFF) provide you with an extensive range of materials offering a variety of beneficial material properties such as ease of print, dimensional stability, durability, and flexibility.

Ultrafuse® PP

Ultrafuse PP is high-performance thermoplastic with low density, high elasticity and high resistance to fatigue.

Ultrafuse® PLA PRO1

Speed, Strength, Versatility and Consistency

Ultrafuse® TPU 64D

The hardest elastomer in BASF Forward AM’s flexible product line

Ultrafuse® TPU 85A & TPU 90A & TPU 95A

Flexible BASF Filament Based on Elastollan® with outstanding non-slip soft touch and abrasion resistance

Ultrafuse® PPSU

For High Temperature Stable Applications

Real-Life Appplications

Discover real life projects and find out more about Additive Manufacturing for the O&P industry in our use cases.

Webinars &Whitepapers

3D Printing Accuracy of Ultracur3D® DM 2505

With Additive Manufacturing, dental models can now be manufactured at high speed and reasonably low cost with unprecedented level of accuracy. In this study, the printing accuracy of our resin Ultracur3D® DM 2505 on the 3D dental printer Organical® 3D Print X1S from Organical CAD/CAM is being examined.

Navigating 3D Printing for the Healthcare Industry

Read our whitepaper to discover more about certifications and regulatory considerations for healthcare applications, 3D printing design workflow for the healthcare industry, material selection for additive manufacturing healthcare projects and real-life use cases.

3D Printing in Orthopedics

In this webinar we’re hosting together with the medtech company Spentys, we will provide a practical framework that helps you choosing the ideal material for different orthopedic applications.

Forward AM Solutions

With our expertise in Additive Manufacturing and chemical technologies, we offer orthopedists a bespoke solution through all steps along the whole 3D printing process – from simulation and design to printing and post-processing.

Our experts are here to unlock the full potential of Additive Manufacturing for a vast array of medical devices.

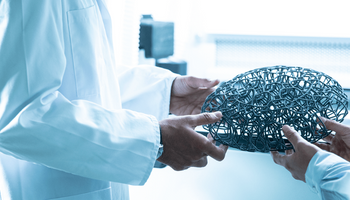

Virtual Engineering

Lattice structures hold tremendous potential for a variety of devices in O&P. Our experts identify and design the optimal lattice structure for each project, cutting development time and cost by minimizing iterations.

Lattice Design

3D-printed lattices are repeated patterns comprised of a network of cells, beams, and nodes. These 3D-printed micro-architectures unlock entirely new designs that have been considered before unmakeable, leading to higher comfort, better rebound, aeration, and reduced weight.

Printing Service

We are here to support O&P professionals with a comprehensive end-to-end solution for their Additive Manufacturing production environment. Our trusted partners guarantee high-quality printed parts – complemented by various post-processing methods to achieve the desired surface finish.

-1.png)