TRUSTED MACHINE MANUFACTURER

Sinterit is a global supplier of 3D printing solutions that empowers

professionals with SLS-enabled capabilities,

the most powerful 3D printing technology.

Sinterit Printers and Materials

.png)

Lisa X

NILS 480

An industrial SLS 3D printer ensuring more automated work and the best ROI on the SLS technology market. With the reinvented productivity in the NILS 480 you can print much more, continously.

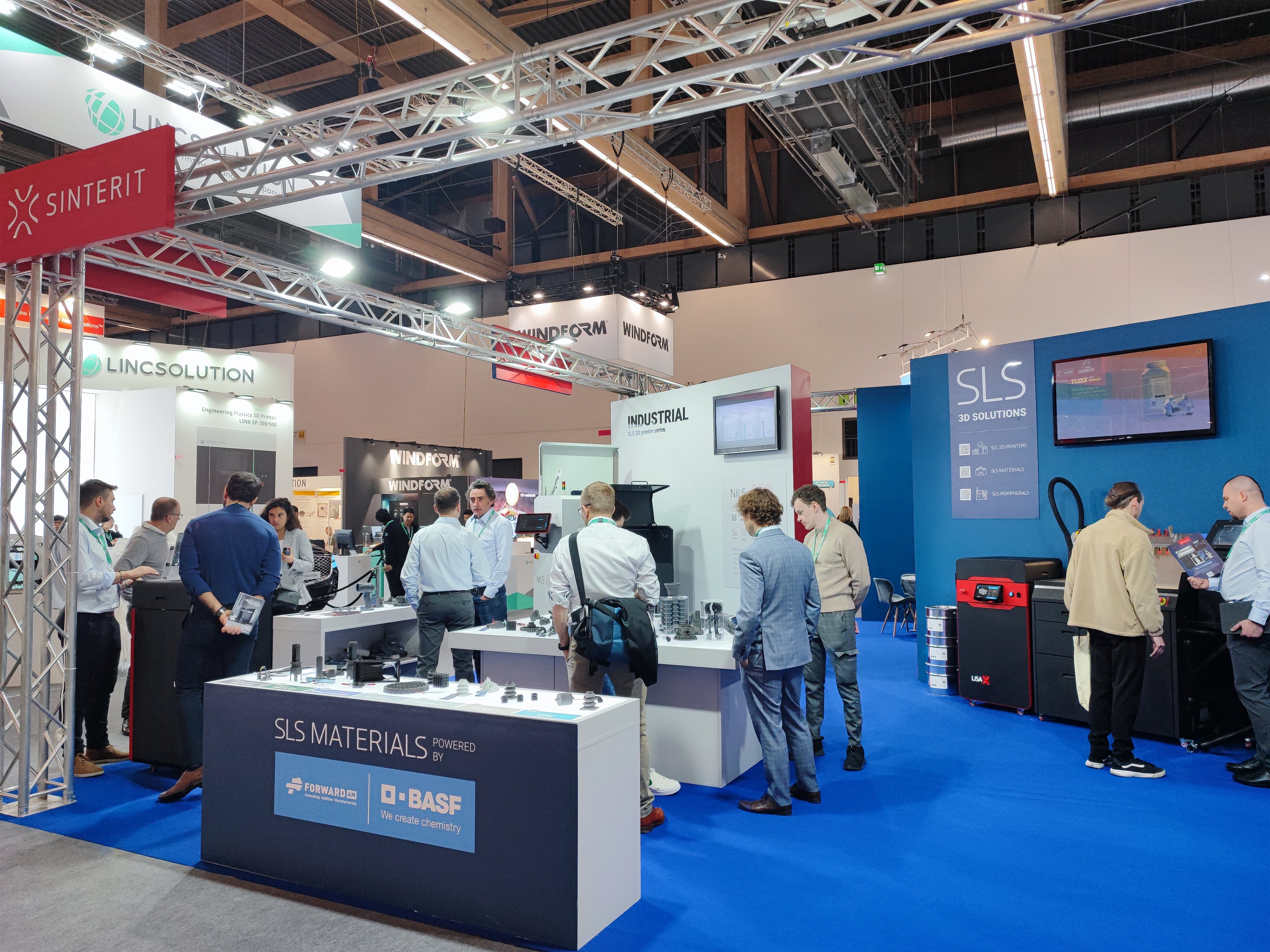

Sinterit and Forward AM have joined forces to push the boundaries of SLS technology and offer innovative 3D printing materials for Industry 4.0. Through collaboration, both companies aim to provide their clients in various industries with advanced solutions that increase productivity, reduce costs, and enable greater autonomy in manufacturing processes. By leveraging their expertise and resources, Sinterit and Forward AM strive to lead the way in SLS technology and offer their customers unmatched capabilities and benefits.

Together we have leveraged our combined expertise and resources to deliver outstanding results. The partnership has yielded innovative 3D printing solutions that have enabled customers to achieve their goals in a more efficient and cost-effective manner. The synergy between both machine and material providers have proved that 1 + 1 can equal 3, and this collaboration is a testament to the power of partnerships in driving progress in the 3D printing industry.

"Our partnership with Forward AM is part of a long-term strategy to develop the widest range of materials and applications in the Compact SLS segment. Sinterit was the first company on the market to develop compact SLS and we are still the most innovative in this field, and a large part of this is the largest portfolio of materials made available to users. We have developed an important part of this portfolio together. Just as important as diversity is the reliability and quality of the materials, so Forward AM is also a natural partner for us.We are constantly working together to develop new materials and refine the current portfolio in line with user needs and sustainability.And above all, Forward AM is a really great team of people with whom we like each other very much and love working together having a lot of fun in creating a better tomorrow for SLS technology."

Real-Life Applications with Sinerit

Somfy reaches for productivity with Sinterit’s SLS technology

Somfy, the world leader in the automatic operation of house and building doors and windows, is also a tech-savvy company. Using additive manufacturing for prototyping purposes, Somfy took a journey from outsourcing to setting up an in-house 3D printing lab. Now it uses the Sinterit’s Lisa PRO and Lisa X SLS 3D printers to achieve even more precision and design freedom.

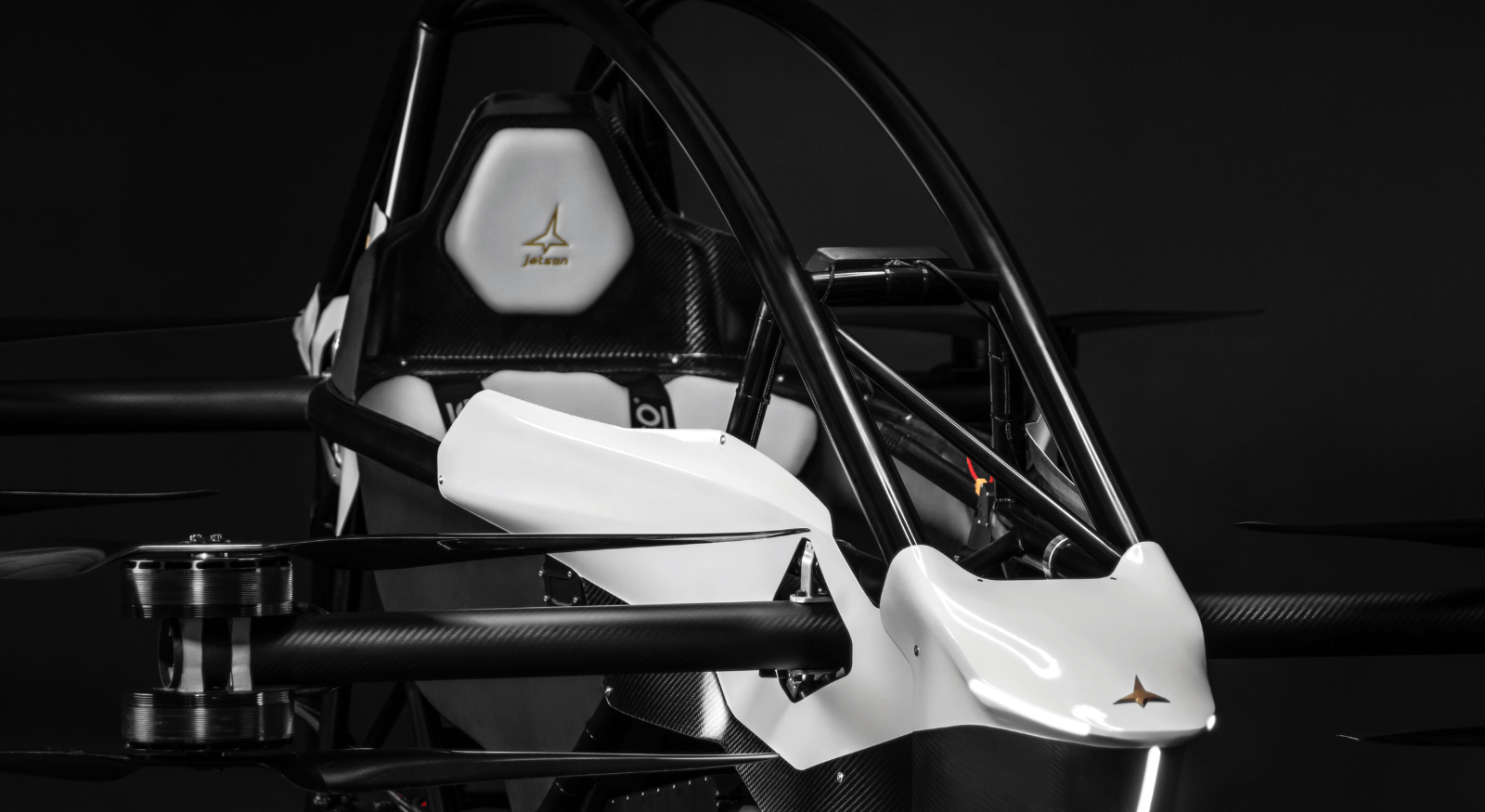

Are you ready for a personal flying vehicle?

Being extremely weight sensitive, Jetson One needed to be manufactured with lightweight methods. And this is where 3d printing jumps (or flies!) in. Additive manufacturing gave Jetson a pretty good leg up in terms of making hollow structures and very narrow lattice patterns, that will make parts stiff and strong enough, but also keep as much of the weight out as possible.