TRUSTED MACHINE MANUFACTURER

Strategic partners since 2013 Farsoon and Forward AM aim to drive 3D printing further then ever before

Farsoon Printers and Forward AM Materials

ST252P

-

ST252P is an open-parameter compact printer

-

Best flexible machine solution for SLS material development and small batch economy production.

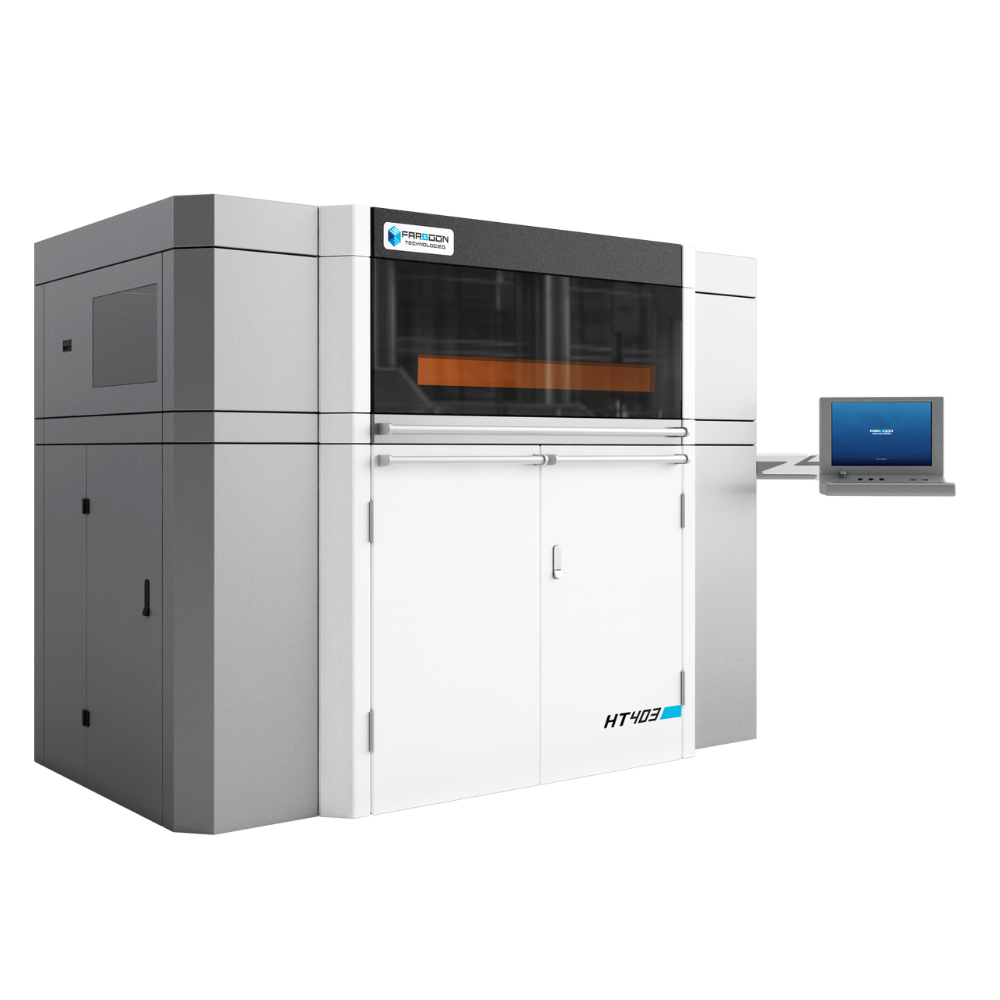

HT403P

-

Flagship production polymer system with an extended envelope size.

-

Enhanced temperature shielding, laser power, and thermal controls

-

Meets needs from value-based prototyping to series production of quality engineering parts.

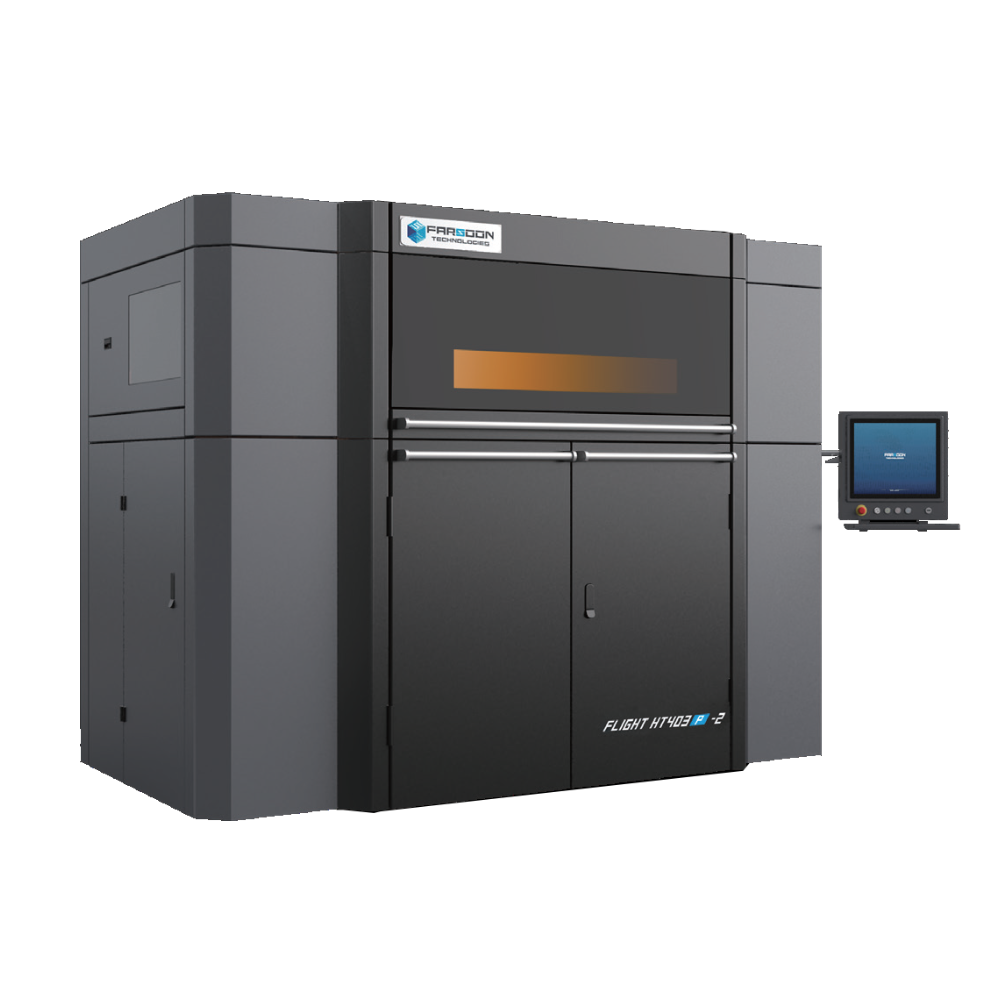

Flight HT403P-2 Dual-laser

- Powerful industrial fiber laser drives industrial-scale series production

- Extended material capability

- Ultimate manufacturing yield & machine turnover rate

- Fast scanning speed of up to 20m/s for each laser

As a strategic partner since 2013, Farsoon has been collaborating with Forward AM on numerous R&D projects with a focus on high-temperature and specialized engineering materials development for laser Powder Bed Fusion technology. The collaboration between Forward AM and Farsoon is a strategic alliance that aims to leverage the strengths of both companies to drive innovation and advancements in the Additive Manufacturing industry.

Our customers benefit greatly from our partnership with Forward AM. Firstly, they gain access to a wider range of advanced materials, which translates into more opportunities for innovation and application versatility. The combination of Farsoon's cutting-edge 3D printing technology with Forward AM's premium materials enables our customers to achieve exceptional print quality, mechanical performance, and functional parts for various industries, from automotive and aerospace to medical and consumer goods.

Farsoon is proud to partner with material leader Forward AM for nearly 10 years, keep supporting industrial customers with our truly open, productive machine solution. The combination of great machine operational flexibility and high-quality engineering material options will allow users to achieve their industrial application success sooner

Real-Life Applications with Farsoon

Sofos adopts Farsoon Flight® Technology for Robotics

Farsoon Technologies first introduced Flight® Technology or Fiber Light® Technology in 2019 offering industry-leading production rates with plastic laser powderbed fusion. In 2021 the Dual-Laser configuration of the Flight® 403P system was announced with even higher productivity. Since then, many of Farsoon’s customers take advantage of the powerful fiber lasers for volume production of high quality, end-use parts.

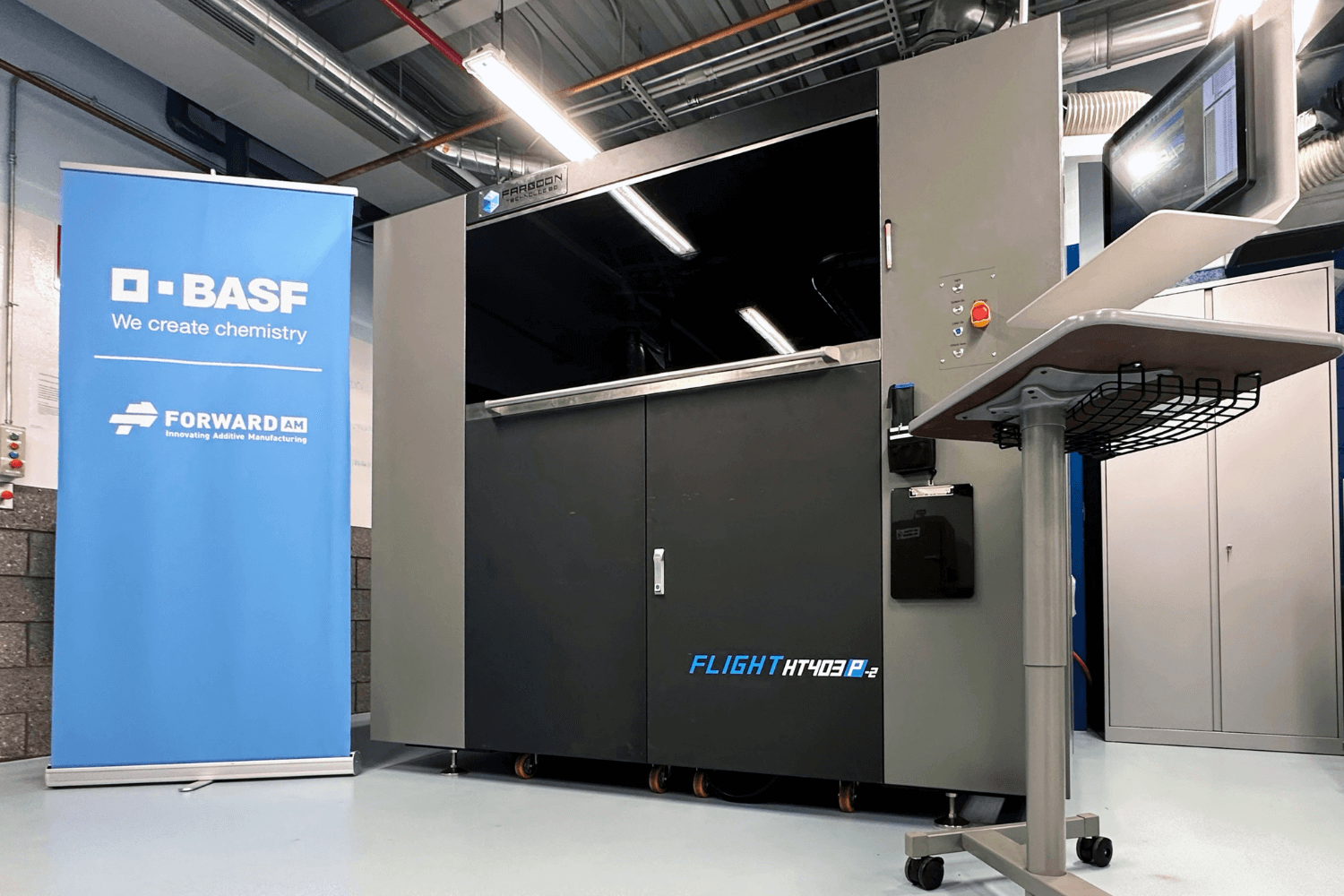

BASF Forward AM invests in Farsoon Dual-laser Flight HT403P-2 3D printer

Farsoon Technologies has announced that BASF Forward AM has invested in one of the company’s Flight Dual-laser HT403P-2 3D printers. BASF Forward AM has been collaborating with Farsoon as a strategic partner since 2013 on R&D projects that focus on high-temperature and specialised engineering materials development for laser powder bed fusion technology.

.png)