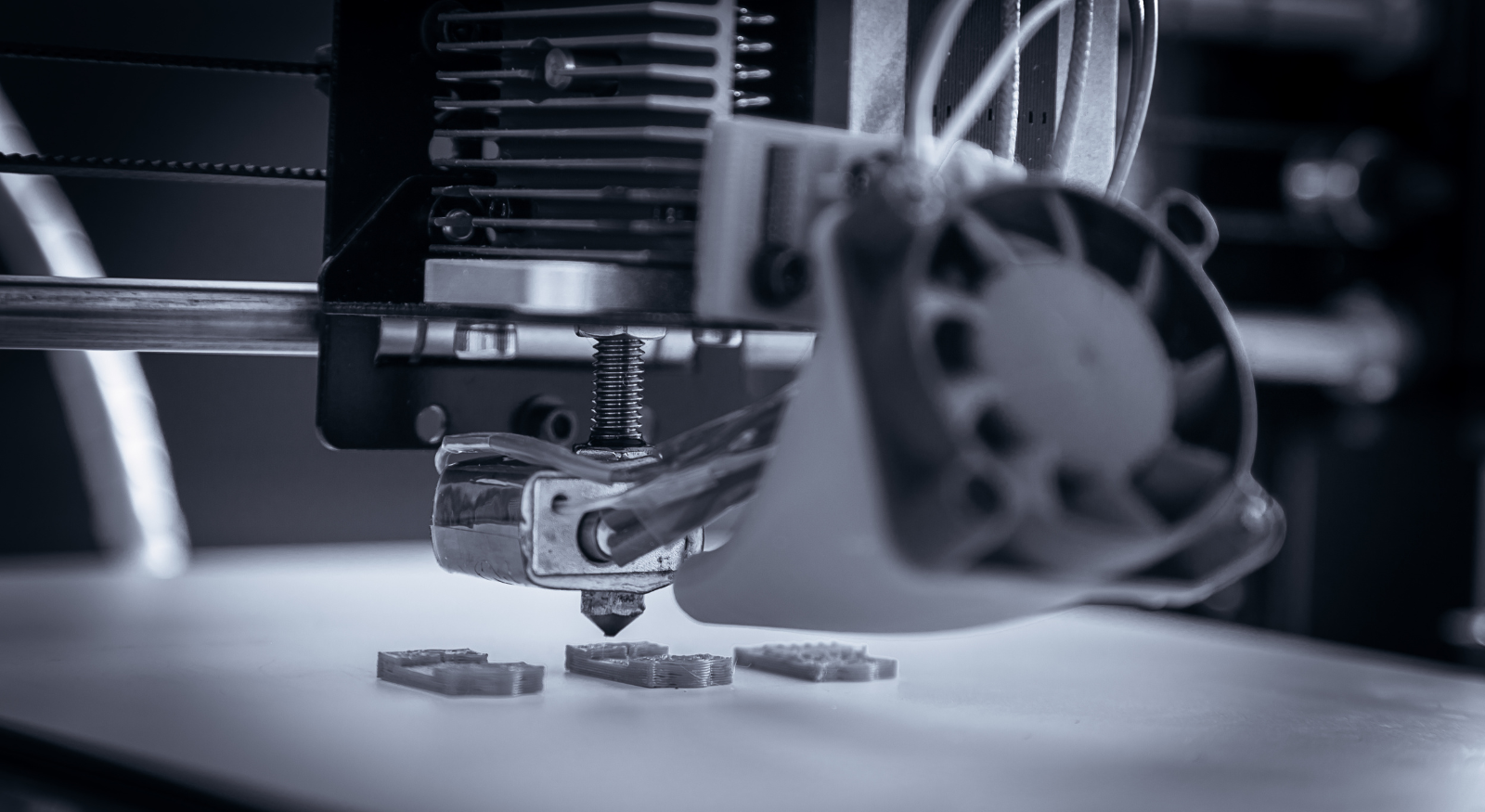

Revolutionize your Factory Floor with Industrial-Grade Additive Manufacturing

Meeting the challenge of an evolving manufacturing infrastructure by empowering your production line with innovative Additive Manufacturing.

With perfect-fit 3D Printing materials and solutions by Forward AM, you can quickly respond to delays or stoppages during the planning and production of your manufacturing aids, spare and end parts, functional prototypes and a variety of other industrial applications.

Interested in getting a free consultation? Arrange a meeting with our experts:

Benefits of 3D Printing in Industrial Applications

Lean Manufacturing

Time & Cost Efficiency

Accelerate development cycles and reduce your

time-to-market process dmkds

Improved Quality

Best-fit characteristics due to a variety of material properties or mix of materials

Freedom of Design

Allows for the creation of lightweight and stable geometries for customized products

What are your manufacturing challenges?

Connect with an expert and discuss how BASF Forward AM can help you in revolutionizing your production line and solve your business problems.

Real World Industrial Applications

Discover the stories behind currently implemented Additive Manufacturing projects and find out more about how these innovative technologies are changing the landscape of industrial manufacturing.

.png)

Manufacturing Aids

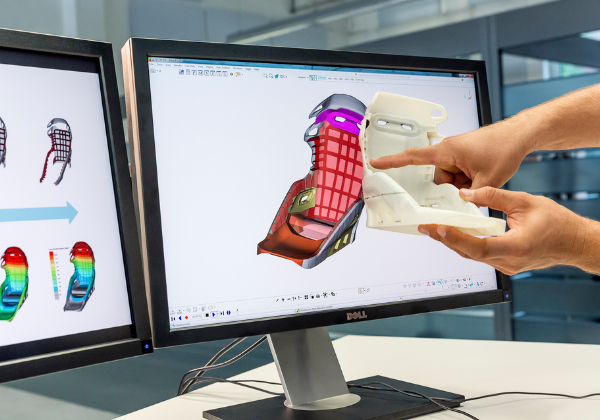

Learn how WKW, a global supplier to Automotive OEMs, produces deep drawing tools with the perfect-fit metal filament material.

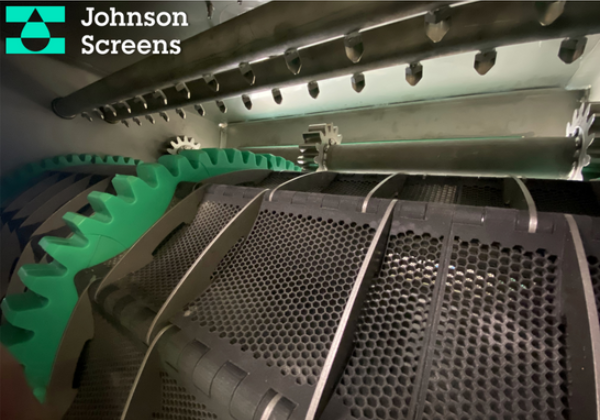

End and Spare Parts

Johnson Screens leverages Additive Manufacturing to deliver complete water filtration solutions to optimize industrial wastewater systems.

Functional Prototyping

-

How Liebherr Components took the first steps in AM with Foward AM's High-performance metal filament and deep simulation expertise. Read more

Recommended Materials and Services for Industrial Applications

TPU Line

Thermoplastic polyurethane (TPU) powder, ideal for the production of parts requiring shock absorption, energy return or flexibility

PP Line

Advanced Polypropylene Powder for a Wide Range of Innovative Applications

PA 11 Line

Deliver extremely accurate print detail and excellent machine compatibility, making them the optimal choice for a broad spectrum of applications from prototyping through to highly specialized system components.

Flexible Filaments

State-of-the-art BASF flexible materials such as Elastollan® for the most demanding industrial applications

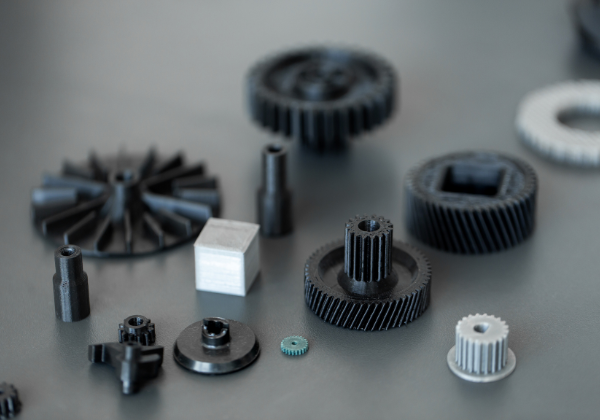

Metal Filaments

Stainless Steel Composite Metal Filaments

Reinforced Filaments

Delivering high stiffness and torsional strength as well as excellent layer adhesion and high dimensional stability.

Rigid Line

Highest flexural modulus of our Ultracur3D® range and the highest heat stability

Daylight Line

Demonstrate high stiffness and flexibility, meeting the needs of customers with demanding applications in 3D printing such as prototyping, engineering and large-scale automotive parts

Tough Line

With finest finishing in our Ultracur3D® range, are specifically engineered for high-detail printing, and provide long-term UV stability

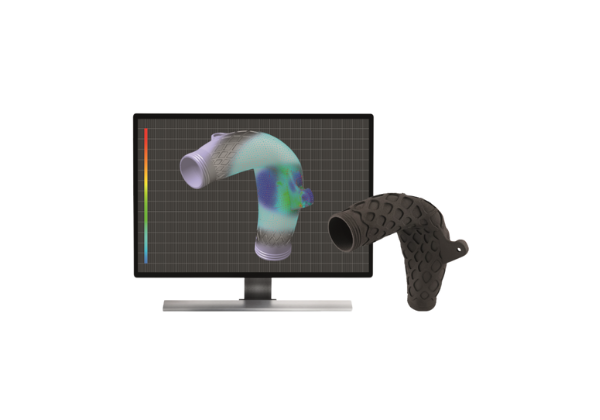

Ultrasim® 3D Services

We offer the right service solution for all stages. Learn how to advance from customization and better aeration using our Ultrasim® 3D Lattice Design, benchmark AM technologies with our Ultrasim® 3D Cost Analysis (TCO), and increase your confidence in part performance using our Ultrasim® 3D Simulation (FEA).

Powders

Our Ultrasint® polymer powders set new standards in Additive Manufacturing for the footwear industry as they enable various applications with flexibility, elasticity, and excellent processability.

Filaments

Flexible Filaments

State-of-the-art BASF flexible materials such as Elastollan® for the most demanding industrial applications

Metal Filaments

Stainless Steel Composite Metal Filaments

Reinforced Filaments

Delivering high stiffness and torsional strength as well as excellent layer adhesion and high dimensional stability.

Photopolymers

Our Ultracur3D® photopolymers are based on BASF‘s decades of experience in polyurethane research and production. Benefit from the broad range of advanced photopolymer resins for footwear applications.

Services

Our engineers can generate, simulate and manufacture lattices finely tuned to our customers' requirements to deliver the best walking experience out of just one material.

Filaments

Ultrafuse® TPU 64D

The hardest elastomer in BASF Forward AM’s flexible product line

Metal Filaments

Stainless Steel Composite Metal Filaments

Ultrafuse® PP GF30

Printing with a High Level of Reinforcement

Liquids

Powders

How to create your first marketing dashboard

Manufacturing Aids

Well crafted landing pages pay dividends. They’re often made out to be an enigma but don’t need to be complicated.

eLearning Center

Webinars

Articles

- Binder Jetting vs. Metal FFF

Learn more about the differences & similarities of metal binder jetting and metal FFF - ESD safe materials

- Top Materials for Jigs and Fixtures

- Large scale 3D printed molds (coming soon)

Blogs

Discover the Extensive Metal Filament World of Forward AM

Metal 3D printing is a great asset. Discover now all the great benefits that Forward AM has to offer within the metal world.

Soft touch tooling and end of arm tooling

In this blog we explore how soft tooling 3D printing works and how it can enhance end-of-arm tooling as well as other applications.

Our Value Chain

Machine Manufacturers

Looking for the right machine manufacturer? We have listed our trusted partners that are here for you.

Distributors

Our regional resellers are the perfect way for you to acquire our products. They are trained by us and have the right knowledge to give you good material advice.

Service Bureaus

We nominated solely providers that convinced us with their high quality standards, fast printing speed and outstanding customer support.

Debinding and Sintering Order Management Portal

Get your printed applications debound and sintered for North America and Europe

Contact us!

Alexander Gengel, our expert in Additive Manufacturing for Industrial Applications, is looking forward to hearing from you.

Downloads